Unveiling Car Frame Damage: Beyond Visual Inspection

Vehicle owners often mistake visible damage for the only indicator of car frame issues, overlooking…….

Car frame damage repair is a specialized art and science, crucial in the automotive industry for restoring vehicles to their pre-accident condition. It involves meticulous techniques to mend or replace damaged structural components of a car’s frame, ensuring safety, stability, and aesthetic appeal. As accidents and collisions are inevitable aspects of modern transportation, the demand for skilled technicians in this field is ever-growing. This comprehensive article aims to guide readers through the intricate world of car frame damage repair, highlighting its importance, techniques, global impact, and future prospects.

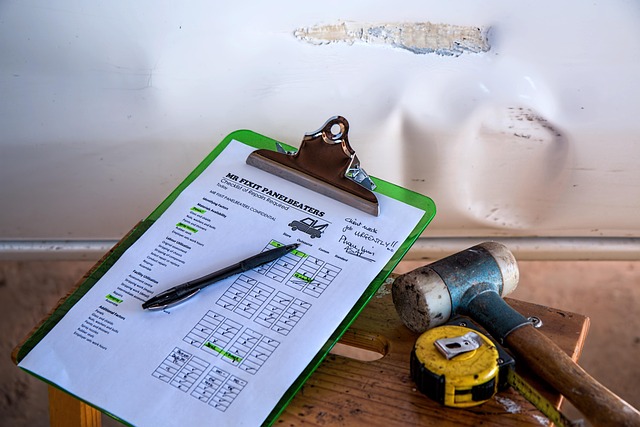

Car frame damage repair, at its core, pertains to the process of repairing or reconstructing the skeletal framework of a vehicle, commonly known as the frame. The frame is a critical component, providing structural integrity and supporting various other parts of the car body. Damage to the frame can occur due to accidents, natural disasters, corrosion, or poor manufacturing processes. Repairing this damage requires a deep understanding of metallurgy, engineering principles, and specialized equipment.

Historically, frame repair techniques have evolved over time, from simple welding and straightening methods to more advanced technologies like computer-aided design (CAD) and robotic welding. The need for precise and efficient repairs has driven innovation in this field, ensuring that vehicles can return to the road safely and with minimal environmental impact.

Key Components of Car Frame Damage Repair:

Car frame damage repair is a global phenomenon, with varying practices and technologies across regions. The impact and trends in this sector are shaped by several factors, including economic conditions, cultural preferences, and regulatory frameworks.

Regional Outlook:

Trends Shaping the Industry:

The car frame damage repair market is a significant component of the global automotive aftermarket, generating substantial revenue and presenting diverse economic opportunities.

Market Dynamics:

Investment Patterns:

Economic Impact:

Technology has been a significant catalyst for progress in car frame damage repair, offering improved efficiency, precision, and sustainability.

Key Technological Milestones:

Future Potential:

The car frame damage repair industry is subject to various policies and regulations that ensure safety, quality, and environmental standards.

Key Regulatory Frameworks:

International Collaborations:

Despite its advancements, car frame damage repair faces several challenges and criticisms that require proactive solutions.

Common Challenges:

Proposed Solutions:

Real-world applications of car frame damage repair offer valuable insights into successful implementation and the potential benefits of advanced technologies.

Case Study 1: Tesla’s Automated Body Shop

Tesla, the electric vehicle (EV) pioneer, has taken a unique approach to frame damage repair with its automated body shop concept. This state-of-the-art facility in Fremont, California, utilizes advanced robotics and AI to streamline repairs. The process starts with an AI-driven quality inspection, followed by automated welding and painting. This method ensures precise, consistent repairs and reduces the time required for complex EV frame repairs. Tesla’s approach showcases the potential of automation in revolutionizing the industry.

Case Study 2: The Volkswagen Group’s Global Repair Standardization

The Volkswagen Group, one of the world’s largest automotive manufacturers, has implemented a global repair standardization program to ensure consistent quality across its brands and dealerships. This initiative involves digitizing repair procedures, providing detailed CAD models, and offering comprehensive training programs. By standardizing repairs, Volkswagen aims to reduce costs, ensure safety, and enhance customer satisfaction worldwide.

Case Study 3: Japan’s Post-Disaster Repair Efforts

Following natural disasters like earthquakes and typhoons, Japan’s automotive industry has demonstrated remarkable resilience through efficient frame repair processes. Local technicians use a combination of traditional skills and advanced technology to restore vehicles quickly. For instance, after the 2011 Tohoku earthquake, Japanese manufacturers and repair shops collaborated to develop standardized repair procedures, ensuring that vehicles could return to the road safely and promptly.

The car frame damage repair industry is poised for significant growth and transformation in the years ahead, driven by emerging technologies, changing consumer preferences, and evolving regulatory landscapes.

Potential Growth Areas:

Emerging Trends:

Strategic Considerations:

Car frame damage repair is a dynamic field that plays a critical role in ensuring vehicle safety, reliability, and environmental sustainability. Through meticulous techniques, cutting-edge technologies, and strategic collaborations, technicians across the globe are restoring vehicles to their pre-accident condition. As the industry navigates challenges and embraces emerging trends, it contributes to a safer, more efficient, and environmentally conscious automotive landscape.

The future of car frame damage repair holds immense potential, with technological advancements promising to revolutionize repair processes, improve customer experiences, and address global sustainability goals. By investing in education, fostering innovation, and adhering to robust regulatory frameworks, the industry can continue to deliver exceptional service while adapting to the ever-changing automotive landscape.

Q: How do I know if my car needs frame damage repair?

A: If you’ve been in an accident or experienced significant impacts, your vehicle may require frame damage repair. Signs include uneven wheel alignment, visible deformities in the body, and unusual noise during driving. A professional inspection is crucial to determine the extent of damage.

Q: What are the benefits of using advanced technologies for frame repairs?

A: Advanced technologies like robotic welding and CAD design offer precision, consistency, and time savings. They ensure high-quality repairs, minimize material waste, and reduce costs in the long run. These technologies also facilitate complex repairs, especially in modern vehicles.

Q: Can I get my car repaired at a regular service center?

A: Most regular service centers are equipped to handle basic frame repairs but may not have advanced technologies. For intricate or specialized repairs, it’s best to visit an independent repair shop or bodyshop specializing in frame damage restoration.

Q: Are there any environmental concerns associated with frame damage repair?

A: Traditional repair methods can generate hazardous waste and emissions. However, the industry is moving towards eco-friendly practices, including the use of recyclable materials, biodegradable solvents, and energy-efficient equipment to minimize environmental impact.

Q: How do I choose a reputable repair shop for my vehicle’s frame damage?

A: Look for shops with certified technicians, a proven track record, and positive customer reviews. Ensure they provide detailed estimates, use high-quality parts, and offer warranties on their work. Reputable shops will also be transparent about pricing and repair procedures.

Vehicle owners often mistake visible damage for the only indicator of car frame issues, overlooking…….

Car frame damage repair feasibility varies based on damage scope and severity, from minor bends corr…….

Car frame damage repair is a critical component of vehicle maintenance, addressing structural integr…….

Car frame damage repair is a critical process that goes beyond visible repairs. Skilled technicians…….

Car frame damage repair is crucial for maintaining vehicle safety and performance after accidents or…….

Car frame damage, often overlooked, significantly impacts vehicle safety and performance as it forms…….

Car frame damage repair for trucks and heavy vehicles is a meticulous, multi-step process requiring…….