Car frame damage repair is a specialized art requiring precision, knowledge, and advanced tools like CAD software and paintless dent repair (PDR). Hydraulic or pneumatic equipment is used to straighten bent frames, with each vehicle model presenting unique challenges. Best practices include meticulous planning, regular equipment maintenance, safety protocols, and continuous training to minimize errors and achieve exceptional results in auto collision repair.

“In the realm of car frame damage repair, mastering frame pulling techniques is paramount for achieving precise and efficient results. This comprehensive guide delves into the intricacies of this specialized process, equipping repair shops with the knowledge to navigate even complex car frame issues.

From understanding the basics of frame pulling to exploring advanced techniques for straightening, we equip professionals with tools to excel. Moreover, by highlighting common mistakes to avoid, this article ensures optimal outcomes in every repair session, fostering a culture of excellence in car frame damage repair shops.”

- Understanding Frame Pulling: The Basics of Car Frame Damage Repair

- Advanced Techniques for Accurate and Efficient Frame Straightening

- Common Mistakes to Avoid During Frame Pulling Operations in Repair Shops

Understanding Frame Pulling: The Basics of Car Frame Damage Repair

Frame pulling is a critical technique in car frame damage repair shops, enabling professionals to straighten and realign damaged vehicle structures. It’s not just about physically moving metal; it’s an art that requires precision, knowledge, and specialized tools. Understanding this process is key when dealing with auto collision repair or vehicle dent repair scenarios, as it directly impacts the overall quality of the car frame damage repair.

This technique involves using hydraulic or pneumatic equipment to apply controlled force on specific points of a bent or damaged frame. By carefully pulling and adjusting metal panels, experts can restore the original shape and alignment, ensuring structural integrity. Proficient auto collision repair technicians understand that frame pulling is not a one-size-fits-all process, as each vehicle has unique design elements. They adapt their methods to accommodate different models, making every car frame damage repair project a customized challenge, ultimately leading to exceptional results in vehicle collision repair.

Advanced Techniques for Accurate and Efficient Frame Straightening

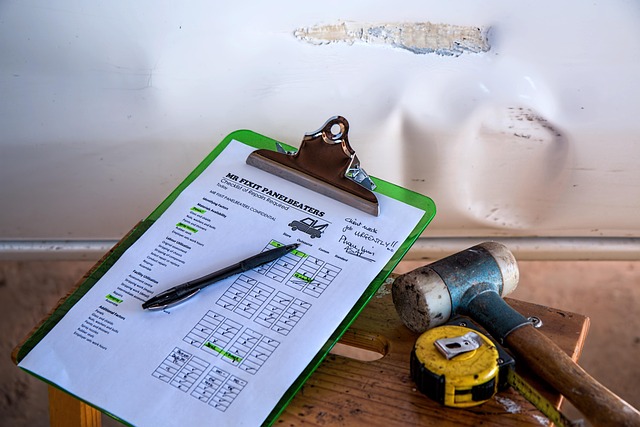

In the realm of car frame damage repair, advanced techniques have revolutionized the way professionals address vehicle structures. Modern shops employ sophisticated equipment and innovative methods to ensure accurate and efficient frame straightening, which is a critical aspect of restoring vehicles to their pre-accident condition. One such technique is the use of computer-aided design (CAD) software that allows for precise measurements and calculations, enabling technicians to identify and correct even the subtlest distortions.

Additionally, the integration of paintless dent repair (PDR) methods has further enhanced the precision and speed of frame straightening. PDR techniques, often combined with specialized tools and trained expertise, minimize the need for extensive welding or body work. This not only reduces repair times but also preserves the vehicle’s original finish, making it a preferred choice in the auto dent repair industry. Furthermore, these advanced practices complement other essential services like auto glass repair, ensuring that every aspect of car frame damage is handled with meticulous care and efficiency.

Common Mistakes to Avoid During Frame Pulling Operations in Repair Shops

In the fast-paced environment of car frame damage repair shops, where precision and efficiency are paramount, avoiding common mistakes during frame pulling operations is essential for achieving top-quality results in auto body repair. One of the primary errors to guard against is excessive force or improper use of hydraulic jacks, which can lead to misalignment or further damage to already fragile structures. Technicians must meticulously plan each step, ensuring that all components are securely braced and supported before initiating any pulling or adjusting procedures.

Another pitfall involves neglecting the importance of regular calibration and maintenance of equipment, such as frame racks and alignment tools. Outdated or incorrectly calibrated machinery can produce inaccurate measurements and irregular results in car body repair processes. Moreover, overlooking proper safety protocols—including wearing appropriate protective gear and ensuring a clear, unobstructed workspace—can increase the risk of accidents and complications during intricate frame pulling tasks. Staying vigilant, adhering to best practices, and continuously updating skills through auto detailing and maintenance training are key to minimizing errors and delivering top-notch services in car frame damage repair shops.

In the realm of car frame damage repair, mastering frame pulling techniques is paramount for achieving precise and efficient straightening. By understanding the fundamentals and employing advanced methods, repair shops can deliver top-notch results while minimizing common pitfalls. With the right approach, these shops become beacons of excellence in the industry, ensuring vehicles return to their pre-damage condition.